What is SCOR?

The Supply Chain Operations Reference (SCOR) model is at the core of everything we do. It is the only comprehensive, universally accepted and open-access supply chain standard used by companies large and small. SCOR gives organizations the ability to assess and improve their company’s supply chain, leading directly to improved business performance.

Use SCOR to analyze, measure and improve your supply chain

By combining elements of business process engineering, leading practices, benchmarking, people skills and a variety of metrics into a succinct framework, SCOR makes it possible to pinpoint core process areas that need optimization.

The value of SCOR

When our clients use SCOR as an end-to-end process blueprint, they not only achieve a remarkable ROI, but other key indices improve as well. Typical results include:

2 to 6 times ROI in the first year

Operating income improvement to 3% of sales

Better return on assets for fixed-asset technology investments

30% faster digital transformation project implementations

Reduction in information technology operating expenses

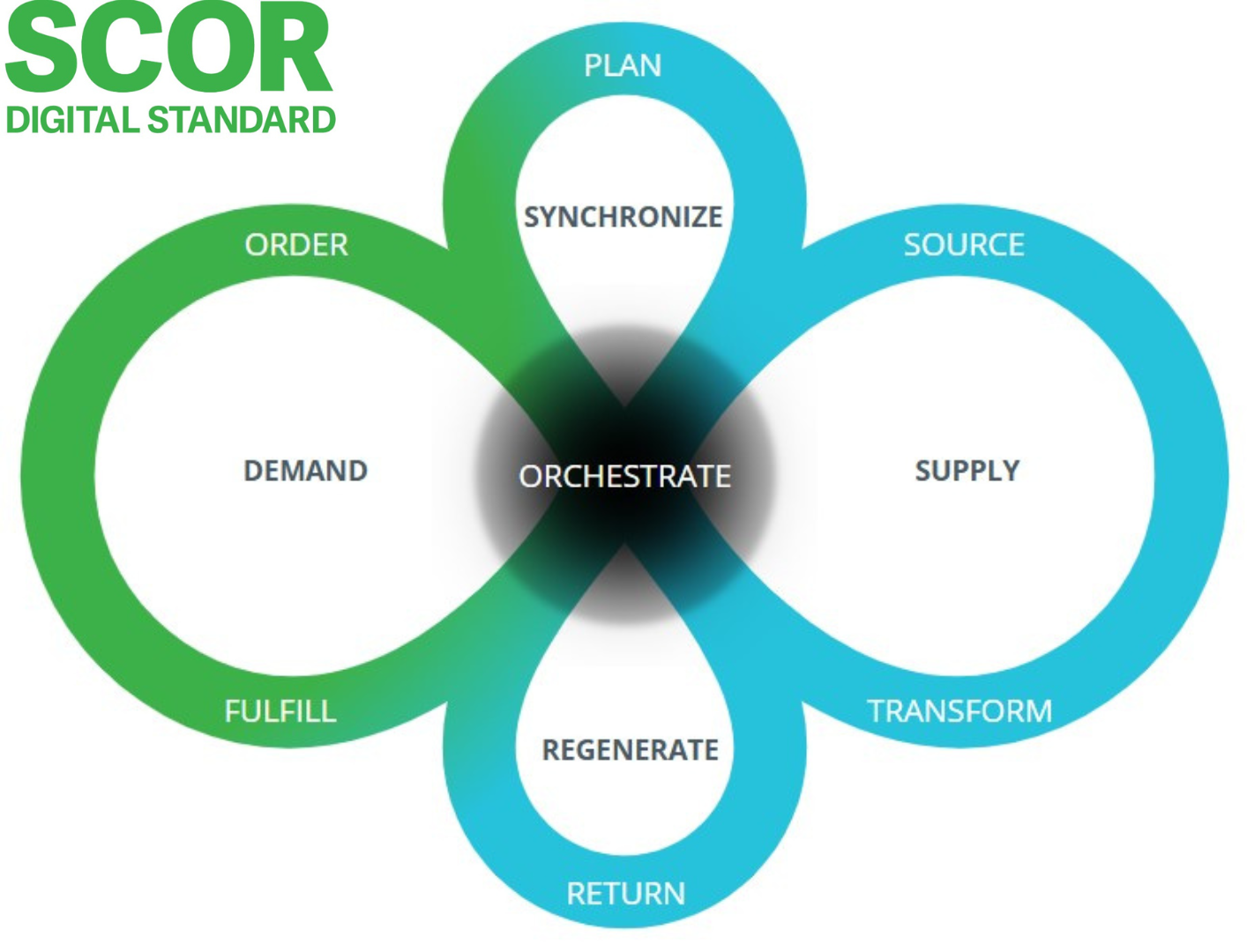

The new Supply Chain Operations Reference Digital Standard (SCOR DS) has introduced the biggest update to SCOR Model Certification since its inception and modernised the framework to include sustainability standards & a digital body of knowledge. This version of SCOR shifts the perspective from a linear supply chain model to a more synchronous supply network. The SCOR DS Model was developed by a distinguished group of subject matter experts. The SCOR DS Model is similar to the SCOR-P certification. In this new model, there have been updates to the processes, skills, metrics, and practices that ensure total coverage across multiple industries.

The SCOR Model describes the business activities associated with all the phases involved in effectively satisfying customer demand. It has been used by thousands of public and private organisations around the world to assess and improve their supply chains, directly leading to improved operational performance.

Levels of ASCM Supply Chain Operations Reference Digital Standard

For each level-1 process, three or more differentiating level-2 processes exist. Each level-2 process contains level-3 process elements. These hierarchical relationships provide process classification.

When conducting a SCOR project, SCOR users may decide to move some lower-level processes, such as those involving sourcing, delivery, and procurement, into other Process sections. SCOR can serve as a flexible and customizable model that can be applied to multiple industries and situations, so the framework process locations are not rigid. If this is done, SCOR users should be careful not to duplicate processes.

Don’t miss your chance to gain an in-depth understanding of the SCOR model and demonstrate your commitment to your organization’s supply chain performance.

The fees include, APICS Membership, SCOR material (soft copy) and 16 hrs of online training divided in 4 session of 4 hrs each & associated Tax, VAT, GST.

The SCOR Model Learning System is divided into 7 primary management processes

-

The Orchestrate stage describes the activities associated with the process integration and system enablement of the supply chain strategies. This comprises of business rules and enterprise activity and resource planning; human resources; elaborate network designs and technologies; data analytics; comprehensive contracts and agreements; timely regulations and compliance; pre-emptive risk mitigation; environment, social, and governance initiatives; circular supply chain management activities; balanced performance management; and much more.

-

The plan stage describes the activities associated with making roadmaps to operate the supply chain effectively. Planning is conducted for the subsequent prcesses – Order, Source, Transform, Fulfill and Return. This includes determining the input requirements; collecting information about the available resources; balancing and matching requirements with resources to determine planned operational capabilities and potential gaps in demand or resource utilization; and identifying the actions needed to correct these gaps.

-

The Order stage describes the activities associated with the purchase of products and services by customers, including attributes like location, methods of payment, pricing of products and services, the status of fulfillment, and any other order data metrics that could provide valuable insight.

-

The source stage describes the activities associated with material procuring, the ordering process, scheduling the order and its fulfillment process, the delivery process, payment collection, and invoicing, and the transfer of products and services.

-

The Transform stage describes the activities associated with the process scheduling and development of products, including production; assembling; disassembling; maintaining, repairing, overhaul functions, and more.

-

The Fulfill stage describes all the activities associated with executing customer orders or services, including scheduling delivery of the order, picking up the order package, packing of the order, shipping processes, installing, commissioning, and regulation complaint invoicing.

-

The Return stage describes the activities associated with the reverse logistic and backward flow of goods and services from the customer to the manufacturer. This includes any service components from a customer through the supply chain network, in order to diagnose challenging conditions, evaluate entitlement, and the disposition back into Transform or other circular activities of the SCOR Model.

By using common definitions among all facets of the supply chain, SCOR creates a standard by which industry professionals can gauge the maturity and effectiveness of a network and understand how it supports business goals. Take a deeper dive into the model:

Results are consistent. Implementing SCOR maximizes process efficiency and overall supply chain performance. Typical results include:Improvement of the operating income.

2x to 6x return on investment in the first year of operation.

Improvement in the return on assets for non-current assets, technology, or capex investments.

30% faster digital transformation in project implementation.

Reduction in IT operating expenses through efficient use of standard system functions.

Improving the ongoing profits by 0.5% – 1% per year.

Learn how to apply SCOR to your supply chain operations.

At the pinnacle of the SCOR Processes hierarchy is Orchestrate level – the Level 0 process “Orchestrate” is at the Strategy level and it conveys and manipulates all of the levels below it.

After the Level-0 processes, SCOR Model recognizes six major Level-1 processes; i.e.: Plan, Order, Source, Transform, Fulfill, and Return.

Why should you choose Trainings with ProKnoWara & Partners?

Passing percentage of participants taking trainings is above 90%.

Get a proper schedule for preparation.

Get connected with APICS certified trainer during and after the training.

Get your doubts solved even after training, till you clear exam.

Understand the subject better as group members share experience from various industry and help to solve your doubts.

Get connected to SCM professional from other top companies which can help for better career opportunities in future.

-

The ASCM Supply Chain Operations Reference (SCOR) Digital Standard is a framework designed to help organizations optimize their supply chain operations. It provides a structured approach to measuring and improving supply chain performance, focusing on processes such as planning, sourcing, production, delivery, and return.

-

The SCOR Digital Standard is intended for supply chain professionals, including managers, analysts, and consultants. It is valuable for those involved in designing, managing, and improving supply chain processes, as well as for organizations looking to enhance their supply chain performance through standardized practices.

-

Implementing the SCOR Digital Standard helps organizations achieve greater efficiency and effectiveness in their supply chain operations. It provides a clear framework for benchmarking performance, identifying improvement opportunities, and aligning supply chain processes with business objectives, ultimately driving better results and competitive advantage.

-

Today, supply chain exists in almost all the fields. The list is quite vast. To name a few…

Manufacturing companies E-Retail

Technology Food & Beverage

Shipping

Automotive

Fashion

Healthcare Oil and Gas

E-Commerce, and so on.

-

Yes, APICS/ASCM Certifications are recognized globally.

-

Being an ASCM member, you get discounts on the course components on the ASCM exams, learning system and Bundles.

Frequently Asked Questions

-

You can make the payment either through Net Banking or Credit Card.

Payment Terms: i. 100% Advance ii. Instalments

-

Yes, you can. Kindly connect with our sales team for further assistance on the same.

-

The Supply Chain Operations Reference (SCOR) model has a digital standard (SCOR-DS) that provides a framework for improving supply chain performance. The SCOR-DS model focuses on processes, performance metrics, practices, and workflows, helping organizations assess and improve their supply chains. While there isn't a specific "scor ds EXAM," the SCOR-DS framework is often learned through training courses and workshops, which may include an assessment or exam to demonstrate understanding and knowledge of the model.

-

The Supply Chain Operations Reference (SCOR) model, now known as SCOR DS (Digital Standard), doesn't have a fixed expiration or validity period for its framework or certifications.

-

Completing an ASCM certification can enhance your skills and qualifications, making you a more competitive candidate in the job market. While it may improve your job prospects and potentially support career advancement, specific outcomes such as getting a job, increment, or promotion will depend on various factors including your experience, current role, and job market conditions. The ASCM certification demonstrates your expertise and commitment to professional growth, which can be valuable for career progression.

-

Training is always beneficial for certifications. You can always connect with the instructor for any doubts or queries related to the study material and have a smooth process towards your exams. KnoWerx instructors have more than 35 years of experience and the passing ratio of KnoWerX candidates is 90%, and too in first attempt.